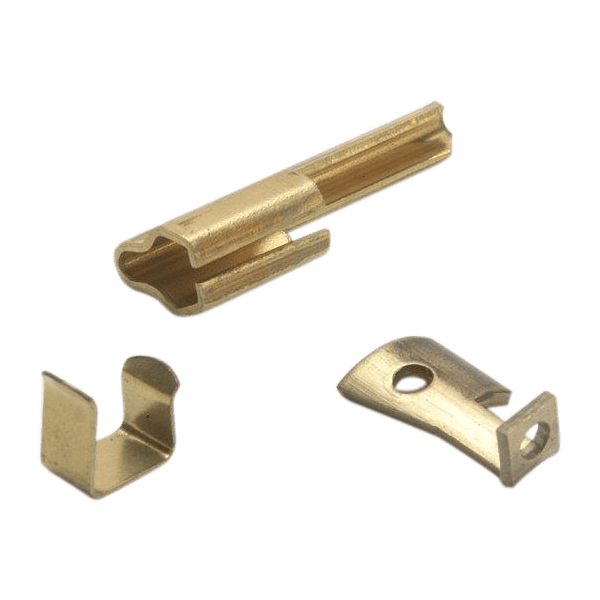

BRASS METAL STAMPING

Brass, an alloy of copper and zinc, can be used to make a wide variety of metal stampings.

The bright gold-like appearance of brass, and its resistance to tarnishing, makes it an ideal candidate for metal stampings that are designed for decorative purposes or where the cosmetic appearance of the stamping is important.

Brass metal stampings are often used in applications where low friction is required; since brass is softer than many other metals, metal stampings made from it can be utilized in situations where it is important that no sparks be struck. Brass metal stampings are often used in plumbing, hardware, fastener, and electrical applications.

Brass metal stampings are most commonly made from the 260 brass alloy, also known as cartridge brass, since it possesses the optimum combination of strength and ductility, while keeping the high form-ability properties of copper.

Depending on the requirements of the brass metal stamping, the 260 brass alloy is available in a wide range of tempers from soft to spring (8#’s hard).

Brass metal stampings can also be made from tin coated brass or tin coated after forming to increase electrical conductivity and solder-ability.