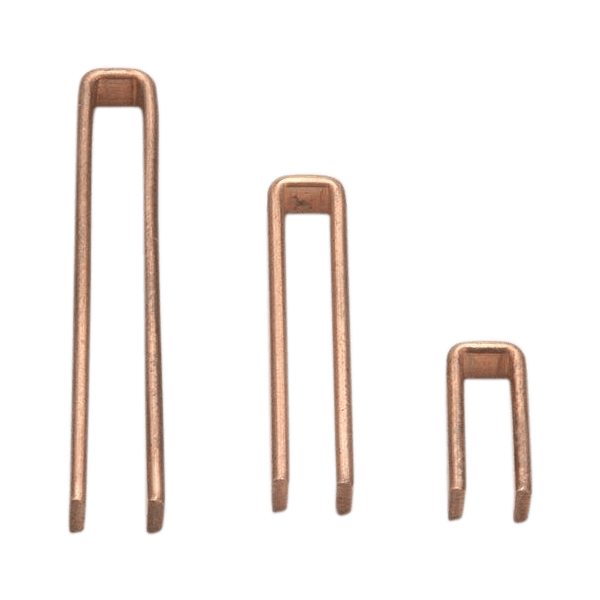

COPPER METAL STAMPING

Copper metal stampings are made from one of the earliest metals to be used by humans. Evidence of the use of copper and its alloys, brass and bronze, date back thousands of years.

Copper is widely used in making metal stampings because it is resistant to corrosion, has superior electrical and thermal conductivity, and is strong, yet easily formed. Copper metal stampings can also be welded or brazed.

Copper metal stampings are used in electrical and electronic products, industrial machinery and equipment, and many consumer products. Examples of copper metal stampings are heat sinks, bus bar, switches, relays, terminals, and contacts.

Copper metal stampings are frequently made from CDA 110 copper, which is called electrolytic tough pitch (ETP) copper, because of its high electrical conductivity. CDA 110 copper is available in a range of tempers, from soft to spring (8#’s hard), which make it suitable for a wide variety of metal stamping applications.