SPRING STEEL METAL STAMPING

Spring steel metal stampings are made from low alloy medium to high carbon steel. Spring steel used in metal stampings is typically in the annealed or soft state as this allows for more intricate and severe forming to take place in the metal stamping operation. Although tempered spring steel is available, the hardness of this material makes severe forming in the metal stamping processvery difficult due to the inherent spring back in the material.

Spring steel metal stampings made from annealed spring steelhave to be heat treated (hardened and tempered) after forming to acquire their “spring properties”, that is the ability to retain or return to their original configuration after significant or repeated pressure. However, such heat treating does carry with it the potential for distortion of the spring steel metal stamping.

Spring steel for metal stampings is typically available in grades 1050, 1070, and 1090 with the higher grades containing more carbon and therefore making the spring steel metal stampingsharder, but also more brittle.

If exposed to harsh conditions, spring steel metal stampings aresusceptible to corrosion (rust) due to the iron content in the metal. To protect the spring metal stamping, or if desired for cosmetic purposes, the spring metal stamping can be plated with a wide variety of coatings and finishes. However, if an electroplating method is used to deposit the coating on spring steel metal stampings they must be again heat treated after plating to relieve hydrogen embrittlement in the spring steel.

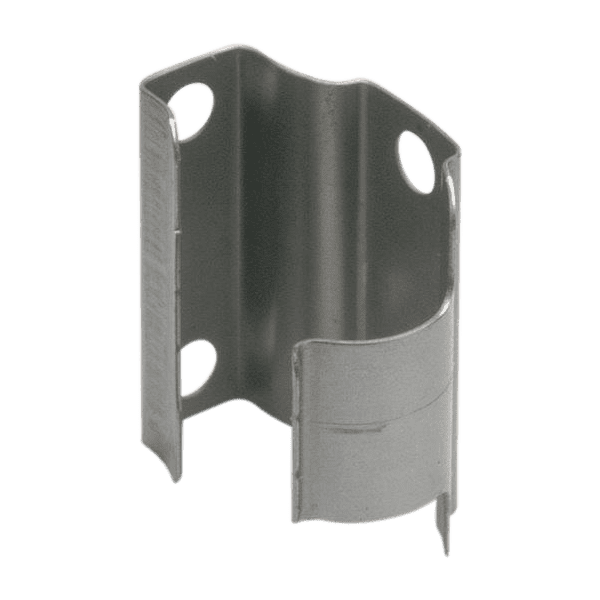

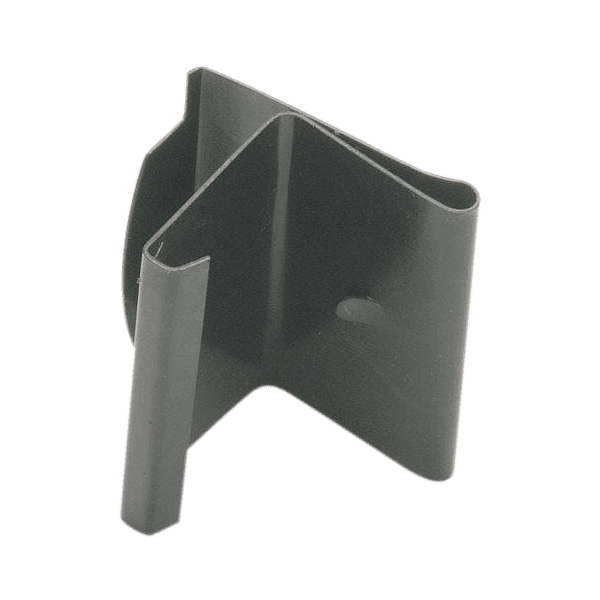

Spring steel if often used to make clips, clamps, and flat springs for use in automotive, appliance and other industrial applications.